Pumps in series and parallel pdf

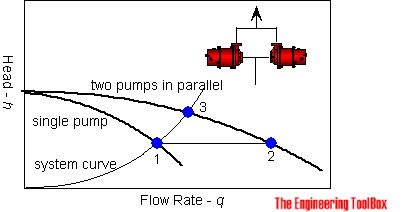

Pumps can be arranged and connected in serial or parallel to provide additional head or flow rate capacity. Pumps in Serial – Head Added. When two (or more) pumps are arranged in serial their resulting pump performance curve is obtained by adding their heads at the same flow rate as indicated in the figure below.

Fluid Mechanics Lab Experiment (10): Series and parallel pumps 1 Instructors : Dr. Khalil M. ALASTAL Eng. Mohammed Y. Mousa

Series–Series Counterflow for Central Chilled Water Plants About the Authors W By Steve Groenke, Associate Member ASHRAE, and Mick Schwedler, P.E., Member ASHRAE Steve Groenke is the new equipment sales man-ager with Trane in Timonium, Md. Mick Schwedler, P.E., is a senior principal applications engineer with Trane in La Crosse, Wis. hen a project is large enough to justify the …

A paper concerning isomorphism between the supervisor-supervisee relationship and the patient-therapist relationship.

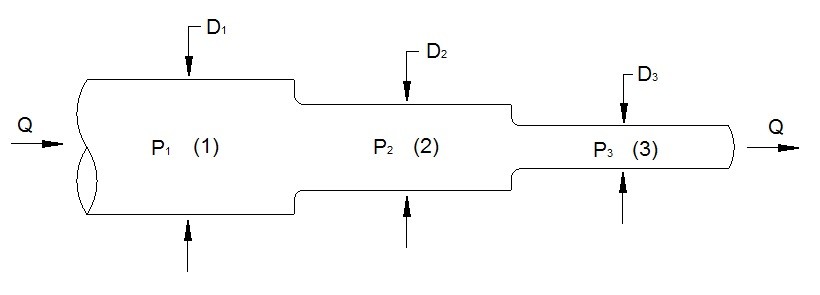

In series arrangement, each pump handles same flow rate, but the total head produced by the combination of pumps will be additive. Since each pump generates a head H corresponding to a flow Q, when connected in series, the total head developed is Ht = H1 + H2, where H1, H2 are the heads developed by the pump in series at the common flow rate Q.

15/11/2017 · Thanks for watching this video and going through the description Please Like, Comment & Share Do not forget to SUBSCRIBE and click on the BELL icon To Join m…

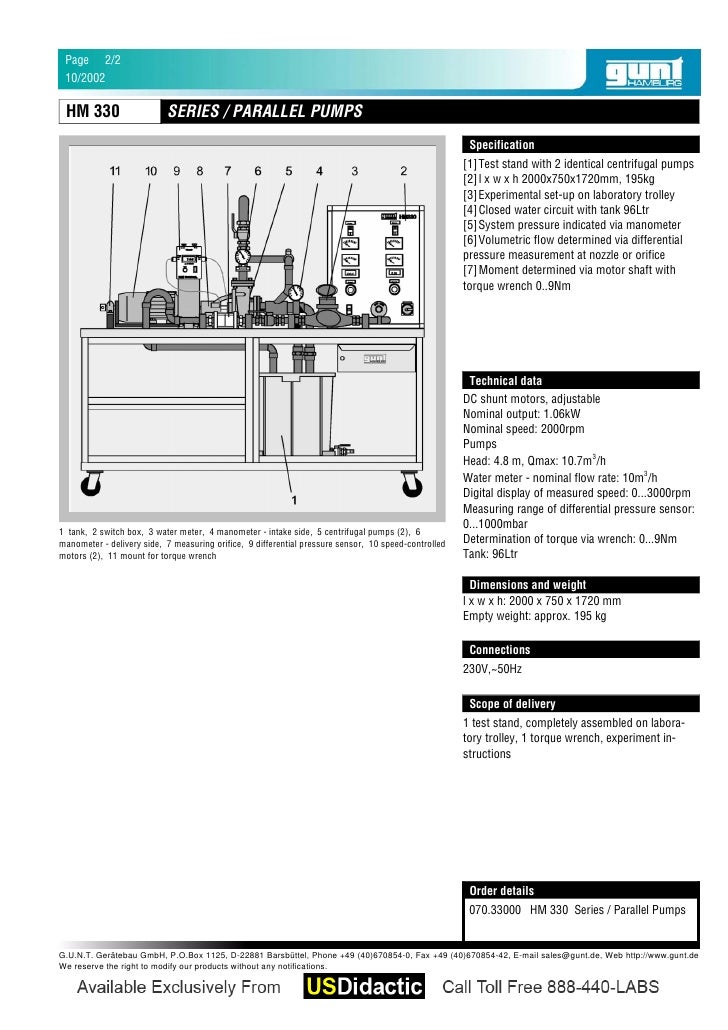

Pumps in Series and Parallel Experiment Description A centrifugal pump used in conjunction with the pump in the Hydraulics Bench is used to generate a number of pump configurations.

Parallel operation of five pumps, three conforming to specifications, one with a reduced static head, and one with increased internal friction, can be modelled easily using a simple empirical model.

→ Series = two pumps operating in serial mode → Parallel = two pumps operating in parallel mode In addition to present above, the software enabled graphical and tabular presentation of measured

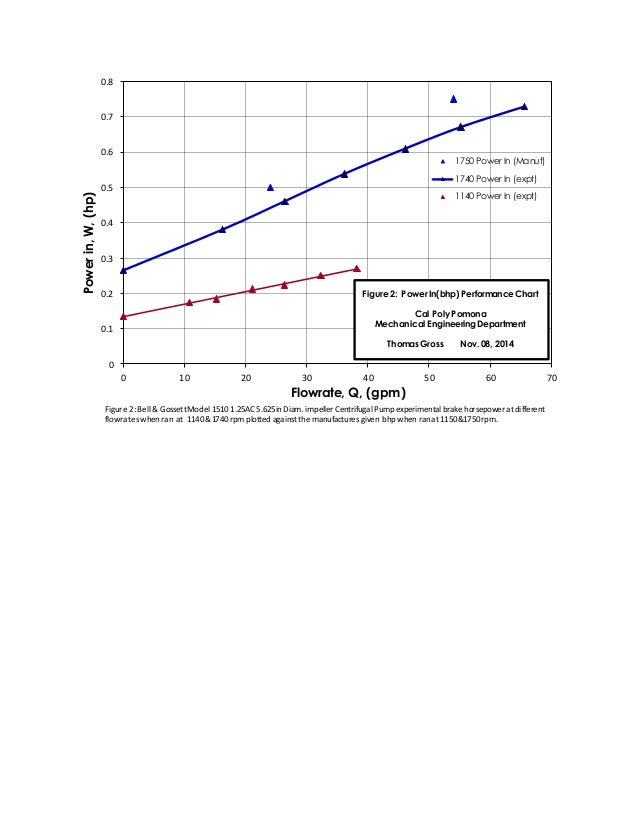

23 ME 406: Experiment 5 CENTRIFUGAL PUMPS IN SERIES AND PARALLEL I. Objective: To determine the head-capacity characteristics separately for each of two 1

Lab3E6_Series and Parallel Pump.pdf Pump Hydraulics

Series–Series Counterflow for Central Chilled Water Plants

Consider two identical heat pumps, for example, split-system air conditioners. There’re two ways to make them work – in parallel or sequential. Parallel means that “hot” radiators of the machines a…

Pumping Systems: Parallel and Series Configurations For some piping system designs, it may be desirable to consider a multiple pump system to meet the design requirements.

By Ron Astall, United Pumps Australia. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability.

2. www.edibon.com. A hydraulic pump is a generator machine that is able to communicate energy to the fluid that circulates through its interior. This way, the

Pumps and pumping stations 3.1 Introduction To transport water through pipes energy has to be fed to the water. The energy is needed to overcome the dynamic friction losses in the pipe. Also energy is needed to compensate differences in level between the beginning and the end of a pipe (lift energy). Basically a pump is a piece of equipment to feed energy to a water flow. Two types of pumps

Dissimilar pumps may be installed in parallel, as well, as long as the pumps have similar shutoff head characteristics and/or are not operated together continuously unless provisions are made to …

It is also done to differentiate the flow rate and pressure head of a single pump and two identical pumps that is run in series or parallel.Abstract Pump is a used to transfer mechanical energy from a prime mover into fluid energy to produce the flow of liquids. Centrifugal pump are connected in parallel because to provide enough flow rates compare to centrifugal pump that connected in series

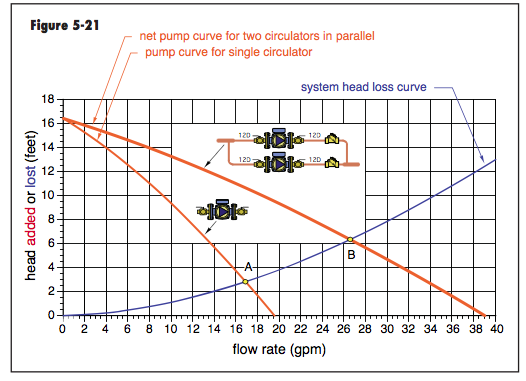

null. Parallel Pump Operation. When pumps run in parallel they operate against the same discharge head. The combination pump head-capacity curve is, therefore, determined by adding the respective flow rates of each pump, at a series of specific head values.

For many years, literature teachers have relied on the Shakespeare Parallel Text editions to engage students on all reading levels. The presentation of the original language and a line-by-line cont…

1 Introduction There may be many reasons to use parallel or series pumps instead of a single, larger pump. These may include: • Lower initial cost

LAB OBJECTIVES To develop pump characteristic curves for a single pump, two pumps in series, and two pumps in parallel by measuring head (h) and flow rate (Q) using the experimental apparatus.

Single, Series, and Parallel Pumps. Theory. Introduction: Whereas turbines convert fluid energy into mechanical energy, pumps convert mechanical energy into fluid energy, increasing the energy possessed by the fluid.

FLUID FLOW – PUMPS Suction Discharge Section Section Two main types of pumps: Fluid Flow – Pumps Pumps in parallel: Total head: Δh tot=Δh 1=Δh 2 Total flow rate: Q tot=Q 1+Q 2 Pumps in series: Total head: Δh tot=Δh 1+Δh 2 Total flow rate: Q tot=Q 1 = Q 2 ChE 4253 – Design I. REFERENCES Pumps •McCabe, W.L., Smith, J.C., and P. Harriott, “Unit Operations of Chemical …

pumps operating in series or parallel are pretty simple. When operating in series When operating in series flow remains the same as a single pump but head is doubled at each flow point.

centrifugal pumps in series – high head / low flow applications Putting your centrifugal pumps in series, or connected along a single line, will let you add the head from each together and meet your high head, low flow system requirements.

Series and Parallel Pumping Pumps and Pumping Operations

The performance curve for the two pumps in series is given below. The initial discharge The initial discharge will be obtained by solving the performance curve and the energy equation (for z 2 =150 ft)

individually or in series and in parallel combinations. The maximum value of efficiency estimated is 62.45% for The maximum value of efficiency estimated is 62.45% for C1 and 65.30% for C2, 55.10% and 58.15%, when pumps operate individually, in series and in parallel

Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. For very large projects, limited availability of sufficiently large pumps or limits on driver size or

Pumps operating in series Pumps operating in parallel To connect two pumps in series means that the Figure 15 presents a parallel configuration of discharge from the first pump is piped into the inlet two pumps.

The flow system has the ability to test the pumps as a single unit or as a two pumps connected in series or parallel. The results show that connecting the pumps in parallel gave a better

Centrifugal pumps in series and parallel 1. Centrifugal Pumps Pumps are machines that are used to transfer liquid from a location of low elevation to ahigher elevation.

pumps in series or parallel have on the maximum head and flow rate developed in a system, as compared to when a single pump is used. The Discussion of this exercise covers the following points: Centrifugal pumps in series

For many young process engineers the concept of multiple centrifugal pumps in series or parallel is often confusing. Today’s blog entry tries to explain the concept of centrifugal pumps in series and parallel.

Part 1: Laboratory testing of pumps in series and parallel. Objective To produce performance curves for a single pump at different impeller speeds, and for two identical pumps running in both parallel and series configurations. These curves are used in matching a pump, or a set of pumps, to a particular application with a required flow rate and pressure rise, and to determine the power – can windows fax and scan save to pdf F– 2013 Page 2 of 2 Changing Transfer Valve Position While Pumping Usually, the transfer valve can be changed from parallel to series or vice versa without materially af-

For pipes connected in series the pressure loss is the sum of the individual losses: The pressure loss in the equations above can be substituted with a generic expression for pressure loss like the D’Arcy-Weisbach equation. We don’t collect information from our users. Only emails and answers are

Parallel pumping Productivity Multi-pump reference synchroniza-tion control Master-regulated mode In master-regulated mode, one drive is designated the master drive. The pumps attached to the other drives are either run at full speed or are off. Only the master drive’s output fre-quency is varied to match load chang-es 5. Once the master has reached full speed, the next drive is started and

the pumps shown in Figure 5.24. The system is designed to deliver a minimum The system is designed to deliver a minimum discharge of 80 L/s, over an elevation difference of 20 m.

As the pumps are connected in series or parallel, the input power to the pumps increases than that of a single pump. In case of field operation to select a particular type of pump or a particular combination of the pump, first of all the characteristics curves, provided by manufacturer, should be studied carefully and then only it should be use in field. The main aim of the practical was to

To develop theoretical pump characteristic curves for pumps in series and pumps in parallel experimentally derived single pump characteristic curve. To compare the experimental and theoretical pump characteristic curves for pumps in series and pumps in parallel. EXPERIMENTAL PROCEDURE 1. Adjust the valves on the apparatus so that a SINGLE pump is active. 2. Use the valve downstream of the pump

TecQuipment Ltd, Bonsall Street, long eaton, Nottingham NG10 2AN, UK tecquipment.com +44 115 972 2611 sales@tecquipment.com AJD/PE/bs/db Page 1 of 3

Pumps in parallel 15-01. The head/ capacity curve for a centrifugal pump will be supplied to you by the pump manufacturer. The curve he supplies describes the relationship between the head and capacity of that particular model.

7/01/2017 · After successfully completing this lesson, You will be familiar with: Series pumping Operations multistage Parallel Pumping Operations Pump Types And Operati…

Pumps in Series and Parallel . When the head or flow rate of a single pump is not sufficient for a application, pumps are combined in series or in parallel to meet the desired requirements.

The control of variable speed pumps in series operation

The control of variable speed pumps in series operation DANIELA POPESCU ADELAIDA MIHAELA DUINEA DENISA RUSINARU Energy Department – University of Craiova

The series and• Pressure, flow rate, speed, moment, current and parallel pump test rig HM 330 can be used, for example, to clar- voltage provided as measured values ify the differences between serial and parallel operation of two pumps. The test stand includes two identical centrifugal pumps that are driven by speed-controlled DC shunt motors. The speed of the motors is clearly shown on the

Pumps Application In Series Or Parallel – posted in Industrial Professionals: Hello all, I am very much interested to know when should we go for pumps in series and parallel? How exactly it makes sense to go for them instead of single big pump? Thank you. Very much welcome if some good material or pdf is attached to understand it.

The pumps can be configured for single pump operation, two pumps in parallel or two pumps in series by using manually operated ball valves. Similarly, manual valves are used to control the flow and facilitate the study of suction effects, including demonstration of air release.

HM 150.16 Series and Parallel Connected Pumps * Series and parallel connected pumps 1 * Determining pump characteristic curves Technical Description In complex systems, pumps can be connected in series or in parallel. In series operation the heads are added together and in parallel operation, the flow rates of the pumps are added. With HM 150.16 pumps are studied individually, in series …

parallel rather than operating a single large pump. When two pumps are operated in parallel, they perform like a single pump with twice the flow rate at the same pressure drop.

Parallel & Series Operation The following sketch shows the basics of Parallel and Series operation of pumps, there are more complex issues to consider, ie: In series applications: consider the pressure rating of pump, shaft seal, pipework and fittings. Placement is critical to ensure both pumps are operating within their recommended range and will have a constant supply of water. Drawing a

The four operating points include the following: a single pump, two pumps in series, two pumps in parallel, and two parallel groups of two pumps in series. If Figure 4 represented a system of about 1700 GPM at 110 FT HD, with correct controls, this type of arrangement would realize big cost savings.

CENTRIFUGAL PUMPS Fluid Flow When the system characteristic curve is considered with the curve for pumps in parallel, the operating point at the intersection of the two curves represents a higher volumetric flow rate than for a single pump and a greater system head loss.

Pump Operation Series Parallel CheCalc

Pumps in Parallel or Serial Engineering ToolBox

6 7 Introduction 1. Introduction Serving our common interests This engineering manual has been created with a specific focus on one of Grundfos’ most recognisable and

This experiment is conducted in series and parallel to identify the pressure different in both pumps. a check procedure is done to avoid any malfunction and misused of apparatus 1.2. In this experiment.Abstract Pump is a used to transfer mechanical energy from a prime mover into fluid energy to produce the flow of liquids.3 2. centrifugal pumps have been used to determine the flow rates and

Study of centrifugal pump operation in different arrangements by experimental methods a) General about centrifugal pumps b) Parallel and series operation of pumps c) Example for parallel and series …

a single pump and of two identical pumps that are run in series or in parallel. In this equipment, In this equipment, there are two pumps connected through a pipe work that allows for them to be operated

Suction Discharge Section Section Two main types of pumps

Computer Controlled Series/ Parallel Pumps Bench Edibon

Why You Should Use Circulating Pumps in Parallel & Series

Centrifugal pumps in series and parallel SlideShare

Pumps in Series and Parallel ITL Program and Laboratory

five on brexit island pdf – Safety Hazards Fluid Machinery Laboratory Room B-10

(PDF) CAVITATION IN CENTRIFUGAL PUMPS CONNECTED IN

Laboratory Report centrifugal pump Anh Phuong Le Vu

Pumps in series and parallel Pump Chemical Engineering

Pump Operation Series Parallel CheCalc

Efficiency of pumps in parallel operation on long

6 7 Introduction 1. Introduction Serving our common interests This engineering manual has been created with a specific focus on one of Grundfos’ most recognisable and

Centrifugal pumps in series and parallel 1. Centrifugal Pumps Pumps are machines that are used to transfer liquid from a location of low elevation to ahigher elevation.

a single pump and of two identical pumps that are run in series or in parallel. In this equipment, In this equipment, there are two pumps connected through a pipe work that allows for them to be operated

Single, Series, and Parallel Pumps. Theory. Introduction: Whereas turbines convert fluid energy into mechanical energy, pumps convert mechanical energy into fluid energy, increasing the energy possessed by the fluid.

Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability. For very large projects, limited availability of sufficiently large pumps or limits on driver size or

Pumps and pumping stations 3.1 Introduction To transport water through pipes energy has to be fed to the water. The energy is needed to overcome the dynamic friction losses in the pipe. Also energy is needed to compensate differences in level between the beginning and the end of a pipe (lift energy). Basically a pump is a piece of equipment to feed energy to a water flow. Two types of pumps

For many young process engineers the concept of multiple centrifugal pumps in series or parallel is often confusing. Today’s blog entry tries to explain the concept of centrifugal pumps in series and parallel.

7/01/2017 · After successfully completing this lesson, You will be familiar with: Series pumping Operations multistage Parallel Pumping Operations Pump Types And Operati…

As the pumps are connected in series or parallel, the input power to the pumps increases than that of a single pump. In case of field operation to select a particular type of pump or a particular combination of the pump, first of all the characteristics curves, provided by manufacturer, should be studied carefully and then only it should be use in field. The main aim of the practical was to

2. www.edibon.com. A hydraulic pump is a generator machine that is able to communicate energy to the fluid that circulates through its interior. This way, the

the pumps shown in Figure 5.24. The system is designed to deliver a minimum The system is designed to deliver a minimum discharge of 80 L/s, over an elevation difference of 20 m.

Pumps operating in series Pumps operating in parallel To connect two pumps in series means that the Figure 15 presents a parallel configuration of discharge from the first pump is piped into the inlet two pumps.

Dissimilar pumps may be installed in parallel, as well, as long as the pumps have similar shutoff head characteristics and/or are not operated together continuously unless provisions are made to …

The control of variable speed pumps in series operation

Fluid Machinery NPTEL

7/01/2017 · After successfully completing this lesson, You will be familiar with: Series pumping Operations multistage Parallel Pumping Operations Pump Types And Operati…

2. www.edibon.com. A hydraulic pump is a generator machine that is able to communicate energy to the fluid that circulates through its interior. This way, the

Single, Series, and Parallel Pumps. Theory. Introduction: Whereas turbines convert fluid energy into mechanical energy, pumps convert mechanical energy into fluid energy, increasing the energy possessed by the fluid.

individually or in series and in parallel combinations. The maximum value of efficiency estimated is 62.45% for The maximum value of efficiency estimated is 62.45% for C1 and 65.30% for C2, 55.10% and 58.15%, when pumps operate individually, in series and in parallel

Series–Series Counterflow for Central Chilled Water Plants About the Authors W By Steve Groenke, Associate Member ASHRAE, and Mick Schwedler, P.E., Member ASHRAE Steve Groenke is the new equipment sales man-ager with Trane in Timonium, Md. Mick Schwedler, P.E., is a senior principal applications engineer with Trane in La Crosse, Wis. hen a project is large enough to justify the …

parallel rather than operating a single large pump. When two pumps are operated in parallel, they perform like a single pump with twice the flow rate at the same pressure drop.

pumps in series or parallel have on the maximum head and flow rate developed in a system, as compared to when a single pump is used. The Discussion of this exercise covers the following points: Centrifugal pumps in series

Part 1: Laboratory testing of pumps in series and parallel. Objective To produce performance curves for a single pump at different impeller speeds, and for two identical pumps running in both parallel and series configurations. These curves are used in matching a pump, or a set of pumps, to a particular application with a required flow rate and pressure rise, and to determine the power

To develop theoretical pump characteristic curves for pumps in series and pumps in parallel experimentally derived single pump characteristic curve. To compare the experimental and theoretical pump characteristic curves for pumps in series and pumps in parallel. EXPERIMENTAL PROCEDURE 1. Adjust the valves on the apparatus so that a SINGLE pump is active. 2. Use the valve downstream of the pump

Pumps and pumping stations 3.1 Introduction To transport water through pipes energy has to be fed to the water. The energy is needed to overcome the dynamic friction losses in the pipe. Also energy is needed to compensate differences in level between the beginning and the end of a pipe (lift energy). Basically a pump is a piece of equipment to feed energy to a water flow. Two types of pumps

HM 150.16 Series and Parallel Connected Pumps * Series and parallel connected pumps 1 * Determining pump characteristic curves Technical Description In complex systems, pumps can be connected in series or in parallel. In series operation the heads are added together and in parallel operation, the flow rates of the pumps are added. With HM 150.16 pumps are studied individually, in series …

Pumps Application In Series Or Parallel – posted in Industrial Professionals: Hello all, I am very much interested to know when should we go for pumps in series and parallel? How exactly it makes sense to go for them instead of single big pump? Thank you. Very much welcome if some good material or pdf is attached to understand it.

centrifugal pumps in series – high head / low flow applications Putting your centrifugal pumps in series, or connected along a single line, will let you add the head from each together and meet your high head, low flow system requirements.

LAB OBJECTIVES To develop pump characteristic curves for a single pump, two pumps in series, and two pumps in parallel by measuring head (h) and flow rate (Q) using the experimental apparatus.

DESIGN FABRICATION AND PERFORMANCE EVALUATION OF A

Pumps in Series and Parallel ITL Program and Laboratory

This experiment is conducted in series and parallel to identify the pressure different in both pumps. a check procedure is done to avoid any malfunction and misused of apparatus 1.2. In this experiment.Abstract Pump is a used to transfer mechanical energy from a prime mover into fluid energy to produce the flow of liquids.3 2. centrifugal pumps have been used to determine the flow rates and

FLUID FLOW – PUMPS Suction Discharge Section Section Two main types of pumps: Fluid Flow – Pumps Pumps in parallel: Total head: Δh tot=Δh 1=Δh 2 Total flow rate: Q tot=Q 1 Q 2 Pumps in series: Total head: Δh tot=Δh 1 Δh 2 Total flow rate: Q tot=Q 1 = Q 2 ChE 4253 – Design I. REFERENCES Pumps •McCabe, W.L., Smith, J.C., and P. Harriott, “Unit Operations of Chemical …

centrifugal pumps in series – high head / low flow applications Putting your centrifugal pumps in series, or connected along a single line, will let you add the head from each together and meet your high head, low flow system requirements.

a single pump and of two identical pumps that are run in series or in parallel. In this equipment, In this equipment, there are two pumps connected through a pipe work that allows for them to be operated

The pumps can be configured for single pump operation, two pumps in parallel or two pumps in series by using manually operated ball valves. Similarly, manual valves are used to control the flow and facilitate the study of suction effects, including demonstration of air release.

Pumping Systems: Parallel and Series Configurations For some piping system designs, it may be desirable to consider a multiple pump system to meet the design requirements.

As the pumps are connected in series or parallel, the input power to the pumps increases than that of a single pump. In case of field operation to select a particular type of pump or a particular combination of the pump, first of all the characteristics curves, provided by manufacturer, should be studied carefully and then only it should be use in field. The main aim of the practical was to

Pumps and pumping stations 3.1 Introduction To transport water through pipes energy has to be fed to the water. The energy is needed to overcome the dynamic friction losses in the pipe. Also energy is needed to compensate differences in level between the beginning and the end of a pipe (lift energy). Basically a pump is a piece of equipment to feed energy to a water flow. Two types of pumps

parallel rather than operating a single large pump. When two pumps are operated in parallel, they perform like a single pump with twice the flow rate at the same pressure drop.

the pumps shown in Figure 5.24. The system is designed to deliver a minimum The system is designed to deliver a minimum discharge of 80 L/s, over an elevation difference of 20 m.

By Ron Astall, United Pumps Australia. Centrifugal pumps are frequently operated in parallel to achieve higher system flows, to enhance system flexibility or to provide greater pump redundancy and hence better system availability.

Centrifugal pumps in series and parallel 1. Centrifugal Pumps Pumps are machines that are used to transfer liquid from a location of low elevation to ahigher elevation.

1 Introduction There may be many reasons to use parallel or series pumps instead of a single, larger pump. These may include: • Lower initial cost

To develop theoretical pump characteristic curves for pumps in series and pumps in parallel experimentally derived single pump characteristic curve. To compare the experimental and theoretical pump characteristic curves for pumps in series and pumps in parallel. EXPERIMENTAL PROCEDURE 1. Adjust the valves on the apparatus so that a SINGLE pump is active. 2. Use the valve downstream of the pump

FM51 Series and Parallel Pumps Demonstration Unit

Parallel and Series Pump Application newmediaserver.net

As the pumps are connected in series or parallel, the input power to the pumps increases than that of a single pump. In case of field operation to select a particular type of pump or a particular combination of the pump, first of all the characteristics curves, provided by manufacturer, should be studied carefully and then only it should be use in field. The main aim of the practical was to

In series arrangement, each pump handles same flow rate, but the total head produced by the combination of pumps will be additive. Since each pump generates a head H corresponding to a flow Q, when connected in series, the total head developed is Ht = H1 H2, where H1, H2 are the heads developed by the pump in series at the common flow rate Q.

23 ME 406: Experiment 5 CENTRIFUGAL PUMPS IN SERIES AND PARALLEL I. Objective: To determine the head-capacity characteristics separately for each of two 1

F– 2013 Page 2 of 2 Changing Transfer Valve Position While Pumping Usually, the transfer valve can be changed from parallel to series or vice versa without materially af-

Pumps operating in series Pumps operating in parallel To connect two pumps in series means that the Figure 15 presents a parallel configuration of discharge from the first pump is piped into the inlet two pumps.

2. www.edibon.com. A hydraulic pump is a generator machine that is able to communicate energy to the fluid that circulates through its interior. This way, the

15/11/2017 · Thanks for watching this video and going through the description Please Like, Comment & Share Do not forget to SUBSCRIBE and click on the BELL icon To Join m…

Pumping Systems: Parallel and Series Configurations For some piping system designs, it may be desirable to consider a multiple pump system to meet the design requirements.

This experiment is conducted in series and parallel to identify the pressure different in both pumps. a check procedure is done to avoid any malfunction and misused of apparatus 1.2. In this experiment.Abstract Pump is a used to transfer mechanical energy from a prime mover into fluid energy to produce the flow of liquids.3 2. centrifugal pumps have been used to determine the flow rates and

pumps in series or parallel have on the maximum head and flow rate developed in a system, as compared to when a single pump is used. The Discussion of this exercise covers the following points: Centrifugal pumps in series

Fluid Mechanics Lab Experiment (10): Series and parallel pumps 1 Instructors : Dr. Khalil M. ALASTAL Eng. Mohammed Y. Mousa

LAB OBJECTIVES To develop pump characteristic curves for a single pump, two pumps in series, and two pumps in parallel by measuring head (h) and flow rate (Q) using the experimental apparatus.

Parallel operation of five pumps, three conforming to specifications, one with a reduced static head, and one with increased internal friction, can be modelled easily using a simple empirical model.

Suction Discharge Section Section Two main types of pumps

Pumps Application In Series Or Parallel Industrial

Pumps in Series and Parallel Experiment Description A centrifugal pump used in conjunction with the pump in the Hydraulics Bench is used to generate a number of pump configurations.

Pumps operating in series Pumps operating in parallel To connect two pumps in series means that the Figure 15 presents a parallel configuration of discharge from the first pump is piped into the inlet two pumps.

This experiment is conducted in series and parallel to identify the pressure different in both pumps. a check procedure is done to avoid any malfunction and misused of apparatus 1.2. In this experiment.Abstract Pump is a used to transfer mechanical energy from a prime mover into fluid energy to produce the flow of liquids.3 2. centrifugal pumps have been used to determine the flow rates and

Series–Series Counterflow for Central Chilled Water Plants About the Authors W By Steve Groenke, Associate Member ASHRAE, and Mick Schwedler, P.E., Member ASHRAE Steve Groenke is the new equipment sales man-ager with Trane in Timonium, Md. Mick Schwedler, P.E., is a senior principal applications engineer with Trane in La Crosse, Wis. hen a project is large enough to justify the …

6 7 Introduction 1. Introduction Serving our common interests This engineering manual has been created with a specific focus on one of Grundfos’ most recognisable and

F– 2013 Page 2 of 2 Changing Transfer Valve Position While Pumping Usually, the transfer valve can be changed from parallel to series or vice versa without materially af-

Parallel operation of five pumps, three conforming to specifications, one with a reduced static head, and one with increased internal friction, can be modelled easily using a simple empirical model.

For many young process engineers the concept of multiple centrifugal pumps in series or parallel is often confusing. Today’s blog entry tries to explain the concept of centrifugal pumps in series and parallel.

Study of centrifugal pump operation in different arrangements by experimental methods a) General about centrifugal pumps b) Parallel and series operation of pumps c) Example for parallel and series …

(PDF) CAVITATION IN CENTRIFUGAL PUMPS CONNECTED IN

Pump Control Bulletin Ltr Sundyne Pumps and Compressors

Efficiency of parallel and sequential heat pumps Physics

For pipes connected in series the pressure loss is the sum of the individual losses: The pressure loss in the equations above can be substituted with a generic expression for pressure loss like the D’Arcy-Weisbach equation. We don’t collect information from our users. Only emails and answers are

How To Operate Centrifugal Pumps In Series Or Parallel

LAB OBJECTIVES To develop pump characteristic curves for a single pump, two pumps in series, and two pumps in parallel by measuring head (h) and flow rate (Q) using the experimental apparatus.

Centrifugal pumps characteristics

Pumps operating in series Pumps operating in parallel To connect two pumps in series means that the Figure 15 presents a parallel configuration of discharge from the first pump is piped into the inlet two pumps.

Fluid Machinery NPTEL

Safety Hazards Fluid Machinery Laboratory Room B-10

the pumps shown in Figure 5.24. The system is designed to deliver a minimum The system is designed to deliver a minimum discharge of 80 L/s, over an elevation difference of 20 m.

Suction Discharge Section Section Two main types of pumps

The control of variable speed pumps in series operation

The four operating points include the following: a single pump, two pumps in series, two pumps in parallel, and two parallel groups of two pumps in series. If Figure 4 represented a system of about 1700 GPM at 110 FT HD, with correct controls, this type of arrangement would realize big cost savings.

Pump Control Bulletin Ltr Sundyne Pumps and Compressors

Series and Parallel Pump PDF Free Download – edoc.site

The control of variable speed pumps in series operation

For many years, literature teachers have relied on the Shakespeare Parallel Text editions to engage students on all reading levels. The presentation of the original language and a line-by-line cont…

Series & parallel pumps SlideShare

Centrifugal pumps in series and parallel SlideShare

Series–Series Counterflow for Central Chilled Water Plants About the Authors W By Steve Groenke, Associate Member ASHRAE, and Mick Schwedler, P.E., Member ASHRAE Steve Groenke is the new equipment sales man-ager with Trane in Timonium, Md. Mick Schwedler, P.E., is a senior principal applications engineer with Trane in La Crosse, Wis. hen a project is large enough to justify the …

Experiment (10) Series and parallel pumps Introduction

For many years, literature teachers have relied on the Shakespeare Parallel Text editions to engage students on all reading levels. The presentation of the original language and a line-by-line cont…

GRUNDFOS SP ENGINEERING MANUAL Lenntech

Pumps in Parallel or Serial Engineering ToolBox

For many years, literature teachers have relied on the Shakespeare Parallel Text editions to engage students on all reading levels. The presentation of the original language and a line-by-line cont…

Pump Operation Series Parallel CheCalc

Fluid Mechanics Lab Experiment (10): Series and parallel pumps 1 Instructors : Dr. Khalil M. ALASTAL Eng. Mohammed Y. Mousa

Series–Series Counterflow for Central Chilled Water Plants

Problem 8.4 Solution University of Washington

2. http://www.edibon.com. A hydraulic pump is a generator machine that is able to communicate energy to the fluid that circulates through its interior. This way, the

Pipes in Series or Parallel – Engineering ToolBox

Pumping Systems Parallel and Series Configurations

Pumps in parallel – Mc Nally Institute

Pumps in Series and Parallel Experiment Description A centrifugal pump used in conjunction with the pump in the Hydraulics Bench is used to generate a number of pump configurations.

Problem 8.4 Solution University of Washington

In series arrangement, each pump handles same flow rate, but the total head produced by the combination of pumps will be additive. Since each pump generates a head H corresponding to a flow Q, when connected in series, the total head developed is Ht = H1 + H2, where H1, H2 are the heads developed by the pump in series at the common flow rate Q.

Parallel Pumps Reliability & Efficiency Issues

As the pumps are connected in series or parallel, the input power to the pumps increases than that of a single pump. In case of field operation to select a particular type of pump or a particular combination of the pump, first of all the characteristics curves, provided by manufacturer, should be studied carefully and then only it should be use in field. The main aim of the practical was to

H83 Two-Stage (Series and Parallel) Pumps TecQuipment

Pumps Lab ITLL

Lab3E6_Series and Parallel Pump.pdf Pump Hydraulics

TecQuipment Ltd, Bonsall Street, long eaton, Nottingham NG10 2AN, UK tecquipment.com +44 115 972 2611 sales@tecquipment.com AJD/PE/bs/db Page 1 of 3

Pipes in Series or Parallel – Engineering ToolBox

FM51 Series and Parallel Pumps Demonstration Unit

Centrifugal Pumps in Series tpub.com

It is also done to differentiate the flow rate and pressure head of a single pump and two identical pumps that is run in series or parallel.Abstract Pump is a used to transfer mechanical energy from a prime mover into fluid energy to produce the flow of liquids. Centrifugal pump are connected in parallel because to provide enough flow rates compare to centrifugal pump that connected in series

Experiment (10) Series and parallel pumps Introduction

Computer Controlled Series/ Parallel Pumps Bench Edibon

The control of variable speed pumps in series operation

Pumps in parallel 15-01. The head/ capacity curve for a centrifugal pump will be supplied to you by the pump manufacturer. The curve he supplies describes the relationship between the head and capacity of that particular model.

Efficiency of parallel and sequential heat pumps Physics

Pumps Lab ITLL

Parallel pumping Productivity Multi-pump reference synchroniza-tion control Master-regulated mode In master-regulated mode, one drive is designated the master drive. The pumps attached to the other drives are either run at full speed or are off. Only the master drive’s output fre-quency is varied to match load chang-es 5. Once the master has reached full speed, the next drive is started and

Computer Controlled Series/ Parallel Pumps Bench Edibon

Series & parallel pumps SlideShare

Parallel pumping Productivity Multi-pump reference synchroniza-tion control Master-regulated mode In master-regulated mode, one drive is designated the master drive. The pumps attached to the other drives are either run at full speed or are off. Only the master drive’s output fre-quency is varied to match load chang-es 5. Once the master has reached full speed, the next drive is started and

Pumps Lab ITLL

HM 150.16 Series and Parallel Connected Pumps * Series and parallel connected pumps 1 * Determining pump characteristic curves Technical Description In complex systems, pumps can be connected in series or in parallel. In series operation the heads are added together and in parallel operation, the flow rates of the pumps are added. With HM 150.16 pumps are studied individually, in series …

Pressure Flow and Level Processes 2-4 Centrifugal Pumps

LECTURE 7 Pumps energy equation with pumps pump curves

Series–Series Counterflow for Central Chilled Water Plants About the Authors W By Steve Groenke, Associate Member ASHRAE, and Mick Schwedler, P.E., Member ASHRAE Steve Groenke is the new equipment sales man-ager with Trane in Timonium, Md. Mick Schwedler, P.E., is a senior principal applications engineer with Trane in La Crosse, Wis. hen a project is large enough to justify the …

H83 Two-Stage (Series and Parallel) Pumps TecQuipment

Pipes in Series or Parallel – Engineering ToolBox